INTRODUCING MATRIX6D

The reconfigurable factory of the future.

matrix6d: the MODULAR, software-defined additive manufacturing platform

From prototype to production — without compromise.

the challenge: scaling additive manufacturing

Additive manufacturing has transformed prototyping, but scaling into real production has always meant trade-offs. Traditional fixed-bed systems can’t adapt fast enough, can’t mix processes fluidly, and can’t scale throughput and capabilities without costly duplication.

MATRIX6D changes that — by replacing rigid machines with a software-defined, modular factory that grows and adapts with you.

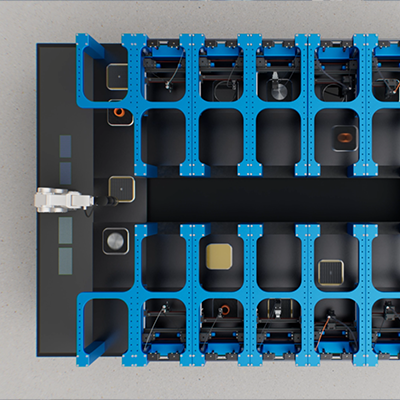

what is matrix6d?

MATRIX6D is the world’s first truly software-defined additive manufacturing platform. Its architecture combines advanced software with modular hardware to deliver infinite scalability, adaptable process extensibility, and flexibility.

-

MOBILE BUILD PLATFORMS (MBPS)

Magnetically levitated carriers that swarm like a fleet of intelligent robots, moving freely across a grid to dock with tool stations. MBPs are managed in real time, routing around bottlenecks and dynamically assigned to maximize throughput.

-

CONFIGURABLE TOOL STATIONS

Each station can be outfitted for an unlimited and ever-expanding universe of materials and tools, including additive (inkjet, aerosol, FFF, SLA, or even Volumetric Additive Manufacturing (VAM) technologies) or non-additive (curing, pick-and-place, inspection) processes.

-

DYNAMIC ORCHESTRATION SOFTWARE

A digital control layer serving as your Traffic Coordinator - managing MBP pathways, the functionality of tool stations, synchronization of multiple projects, and ensuring maximum efficiency across the entire platform.

-

SELF-CALIBRATING PRECISION

Every step is monitored with vision and laser systems, keeping micron-level accuracy across even the most complex workflows.

With MATRIX6D, you don’t buy a single machine. You deploy a living system—a flexible grid that can expand, reconfigure, and evolve alongside your business.

HOW MATRIX6D CHANGES THE GAME

Breaking Barriers in Manufacturing — Speed. Scale. Flexibility.

-

MATRIX 6D’s Solution: MBPs swarm in parallel, dynamically routing to avoid idle time and deliver optimal output.

-

MATRIX6D’s Solution: Replace your multiple single-purpose machines with one modular, reconfigurable, cohesive hardware and software solution, minimizing time and cost.

-

MATRIX6D’s Solution: Add tool stations or MBPs as needed; capacity grows on demand.

-

MATRIX6D’s Solution: Run multiple parts and projects at once, each optimized independently.

-

MATRIX6D’s Solution: Able to seamlessly integrate new and emerging tool technologies within a software-defined architecture.

KEY APPLICATIONS

-

PRINTED ELECTRONICS

Deposit conductive traces, insulators, and embed components in one seamless process.

-

CONSUMER PRODUCTS

Manufacture anything from eyewear to dental aligners on the same machine.

-

HYBRID MICROELECTRONIC PACKAGES

Integrate substrate, semiconductors, optics, and sensors in a single build.

-

MASS CUSTOMIZATION

Deliver personalized consumer goods and wearables at scale without fixed tooling.

-

RAPID PROTOTYPING TO PRODUCTION

Move from concept to scaled manufacturing on the same flexible platform.

-

SPECIALIZED SHORT RUNS

Produce high-value, low-volume parts with unmatched agility.

BENEFITS OF MATRIX6D

A CLEAN-SHEET REIMAGINING

Built as a modular factory, not a monolithic printer.

SWARMING MPBS

Intelligent, autonomous carriers that keep every station fully utilized.

SOFTWARE-DEFINED MANUFACTURING PLATFORM

Real-time flexible manufacturing guarantees maximum efficiency.

fUTURE-PROOF ARCHITECTURE

Expand with new tool stations, materials, and processes—including emerging technologies like VAM.

HOW IT WORKS

-

1

Upload CAD models to the Matrix6D cloud service.

-

2

Matrix6D middleware assigns tasks and plans MBP swarm traffic.

-

3

MBPs levitate, move, and dock at tool stations—executing additive and non-additive steps.

-

4

Multiple MBPs operate in parallel, dynamically routing for uninterrupted flow.

-

5

Diverse projects run side-by-side, each optimized by the Matrix6D intelligence software platform.

LEADERSHIP

let’s work together

Schedule a consultation to discuss how Matrix6D can help you.